Environmental Protection

Reducing the negative impact of our operations on the environment is an important long-term goal.

PhosAgro seeks to minimise the negative impact of its activities on the environment. Our environmental protection strategy is guided by the Russian Federation's environmental doctrine, current environmental legislation, governmental orders and our own environmental strategy.

Our key activities in this area include:

- Efficient use of raw materials and energy resources;

- Construction of new production facilities, and modernisation and technical re-equipping of existing facilities, using the best available technology and technical solutions;

- Introduction of automated control systems for production processes, including control over emissions of pollutants;

- Reduction of the discharge of pollutants by the Company's enterprises into the atmosphere and surface water by improving air and water treatment systems;

- Reduction in the production of by-products that require long-term storage and increasing the amount of re-processing of secondary raw materials;

- Increasing the energy efficiency of production capacities through use of secondary energy sources, energy-efficient equipment, decreasing losses in power and heat networks, all resulting in a decline in the use of primary energy sources and the emissions associated with such sources;

- Measures to reduce the environmental impact of waste storage by improving how we use them and adopting new environmentally safe practices;

- Continuous improvement of the Company's environmental management system (EMS), which is based on ISO 14001:2004 environmental standards, EU environmental protection directives and international agreements, including the Basel Convention, the Helsinki Convention etc.

PhosAgro's downstream facilities have achieved ISO 14001:2004 Environmental Management System certificates, which are confirmed as needed. In 2013, we plan to complete ISO 14001:2004 certification for Apatit.

Exposure assessments, international format safety data sheet, and recommendations for safe handling and first aid measures are developed in compliance with the requirements under the European Regulation No 1272/2008 on classification, labelling and packaging and No 1907/2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) in the development of exposure scenarios.

During 2012, we experienced no accidents or emergencies that could have caused a negative impact on the environment, and our statutory payments for negative impact on the environment in 2012 were largely unchanged compared to previous periods.

Our plans to construct new ammonia, NPK and PKS capacities will lead to an overall increase in our environmental liabilities due to the expanded scale of our operations. However, we believe this impact will be minimal due to our accepted practice of using only the best available techniques for new investment projects. For example, nitrogen oxide emissions for the new ammonia plant will be restricted to under 20 ppm.

Environmental Initiatives

Air Quality

All of PhosAgro's enterprises are equipped with modern exhaust gas purification systems. Each enterprise has set up its own environmental protection department, which monitors atmospheric emissions and air quality.

The underground crushing facilities at Apatit are equipped with gas handling and dust capture systems. The amount of dust from the tailing dumps is minimised by using chemical compounds to form a crust on the dust-generating surfaces as well as by replanting and biologically restoring the dumps. In 2012 we spent approximately RUB 130 million on these activities. We also continued implementation of a program to minimise dust formation, which prevented 3.7 thousand tonnes of dust from entering the atmosphere from tailing dumps at Apatit, thereby reducing overall dust emissions in 2012 four-fold compared to 2011, to 136 tonnes of dust.

Greenhouse gas emissions declined significantly at our ammonia production line to 370 thousand tonnes of CO₂ on an annualised basis. This was a result of our use of these gasses in the urea production process at our new urea line launched in the second half of 2012.

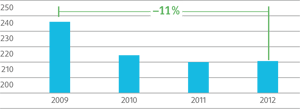

Successful implementation of programmes and projects for technical upgrades at our production facilities in accordance with our environmental strategy has enabled us to significantly lower emissions of pollutants into the air in recent years.

Emissions into the air per unit of production kg/t

Water Treatment

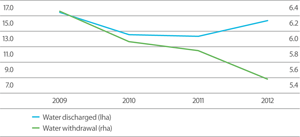

In 2012 we upgraded Apatit's water intake mains from Lake Imandra. This contributed to a reduction in fresh water used by Apatit and by PhosAgro as a whole. At Apatit's Vostochny mine we installed a system of wells designed to reduce the overall groundwater level, thus enabling us to eliminate contamination of the groundwater. While water withdrawal volumes declined in 2012, the increased volume of water discharge was due to the sharp increase in the inflow of floodwater, mainly into the tailings dump at Apatit.

At Balakovo Mineral Fertilizers we have the only fertilizer-manufacturing site in Russia with a closed water circulation system that does not discharge wastewater into the regional water basin. The introduction of this technology is especially important for the company, as it is located in the Saratov region in the vicinity of the river Volga.

At PhosAgro-Cherepovets we continuously carry out inspections of the water-based phosphogypsum removal systems and its sludge storage facility, as well as conducting geomonitoring of the groundwater. Our main objective is to avoid potential contamination of the groundwater. In the phosphate complex of PhosAgro-Cherepovets we are reconstructing the water treatment facilities in order to increase the throughput of our wastewater treatment facilities. Our modernisation efforts have enabled us to reduce the use of fresh water to 24% below the limit.

| Total PhosAgro water withdrawal, 000 m³ | 78,877 |

|---|---|

| Including: | |

| Apatit | 49,616 |

| PhosAgro-Cherepovets | 22,513 |

| Agro-Cherepovets | 0 |

| BMF | 6,748 |

| Total PhosAgro water discharge, 000 m³ | 210,752 |

|---|---|

| Including: | |

| Apatit | 200,385 |

| PhosAgro-Cherepovets | 10,367 |

| Agro-Cherepovets | 0 |

| BMF | 0 |

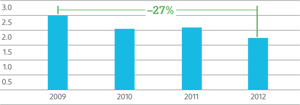

Emissions into surface water per unit of production and water intake per unit of production m³/t

Energy efficiency

We continued our energy saving and energy efficiency programmes in 2012. This programme is for the period until 2015 and was developed in full compliance with the Federal Law № 261-FZ "On energy saving and energy efficiency and on Amendments to Certain Legislative Acts of the Russian Federation" dated 23 November 2009.

In accordance with the accepted system of classification, activities under this programme are divided into two main categories:

- Priority activities intended to improve energy efficiency at our subsidiaries;

- Activities aimed at increasing the reliability and safety of energy supply at the facilities.

In the second half of 2012 we also commissioned a state-ofthe- art urea production line and a new 32 MW gas turbine.

The new urea capacity has allowed us to almost fully utilise the carbon dioxide (a major greenhouse gas) resulting from the production of ammonia, while the gas turbine power plant almost completely covers the company's electricity needs. These new facilities have significantly improved our energy efficiency levels. With the new power generation capacity at PhosAgro-Cherepovets, our overall electricity capacity has reached 134 MW, making PhosAgro-Cherepovets about 85% self-sufficient in energy.

PhosAgro electricity consumption per unit of production (kWh per tonne)